Dr. Amir Khajepour did not realize how much industry demand there would be for his robot when he first began to design it. The original design was done as part of an advanced research project involving high-speed robots, conducted at the University of Waterloo (UW), and used Maple™ to develop key elements of the design. Following the completion of the DeltaBot, a robot based on an innovative cable-actuated delta-style design, Dr. Khajepour received a surprising number of requests from industry for its use. Based on this commercial demand Dr. Khajepour established AEMK Systems (www.AEMKSystems.com), a company specializing in the design and distribution of high-speed, cable and vision-based robotics systems for use in a variety of industrial applications.

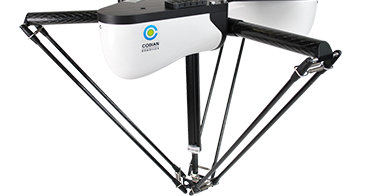

The AEMK DeltaBot robots use cables instead of rigid arms to reduce moving inertia and mechanical equipment costs. The simple design and scalability of the DeltaBot means that it can easily integrate into existing automation environments. The DeltaBot is capable of over 120 pick-and-place cycles per minute. One of the distinctive features of the DeltaBot over other delta robots is its high payload capacity. While other delta robots are limited to payloads under 3 kg, the DeltaBot is capable of handling up to 20 kg. Its high speed, low maintenance costs, and high payload capacity make it a very attractive industry alternative in many automation applications.

Early in the initial research phase, Dr. Khajepour chose Maple, Maplesoft’s advanced technical computing software, as a key tool in the UW robot research project. All subsequent design improvements and enhancements to the Deltabot system were developed using Maple and MapleSim™, Maplesoft’s high-performance physical modeling and simulation solution. Maple and MapleSim are built on a foundation of advanced symbolic computation technology, which lets users obtain highly accurate results. Maple and MapleSim provide insight into the problem structure, allowing users the flexibility to quickly develop ideas and conclusions about the system behavior. “Maplesoft technology was an integral part of the design process of the DeltaBot system, and is now an integral part of the robot’s ongoing development,” says Dr. Khajepour, President and Founder of AEMK Systems, and UW Professor of Mechanical Engineering. “With the use of Maplesoft technology, the initial development time for the robot was significantly reduced, and we continue to benefit from shorter development cycles as we make enhancements to our products.”

AEMK Systems is currently using MapleSim to model and simulate the DeltaBot system for use in real-time hardware-in-the-loop (HIL) testing, as part of its ongoing research and development program. When converting the concise model equations to real-time source code, the code generation tools in MapleSim apply additional optimization steps, further improving simulation speed so the results can be used in real-time systems. “By using MapleSim and Maple, we will be able to design and test enhancements to the DeltaBot much more quickly than with other design tools,” says Dr. Khajepour. “These products make it possible for us to be very responsive to the needs of our customers and the changing demands of industry.”

Download Whitepaper: Maplesoft Software

Used in Advanced Engineering Research

Contact Maplesoft to learn how Maple can be used for your projects

Contact Maplesoft to learn how Maple can be used for your projects