User Case Study:

Researchers at the University of Waterloo use MapleSim in New Approach to Tire Modeling

Challenge

Ideally, a tire model must accurately simulate the dynamics of the system and result in simulations that execute quickly. Unfortunately, existing tire models typically either do not model behavior to a high degree of accuracy, or they are very resource intensive and slow to simulate. Researchers at the University of Waterloo wanted to see if they could develop a new tire model that delivered a better balance between accuracy and efficiency.

Solution

Using MapleSim, the researchers developed a volumetric tire model intended to provide accurate results more efficiently than other models.

Result

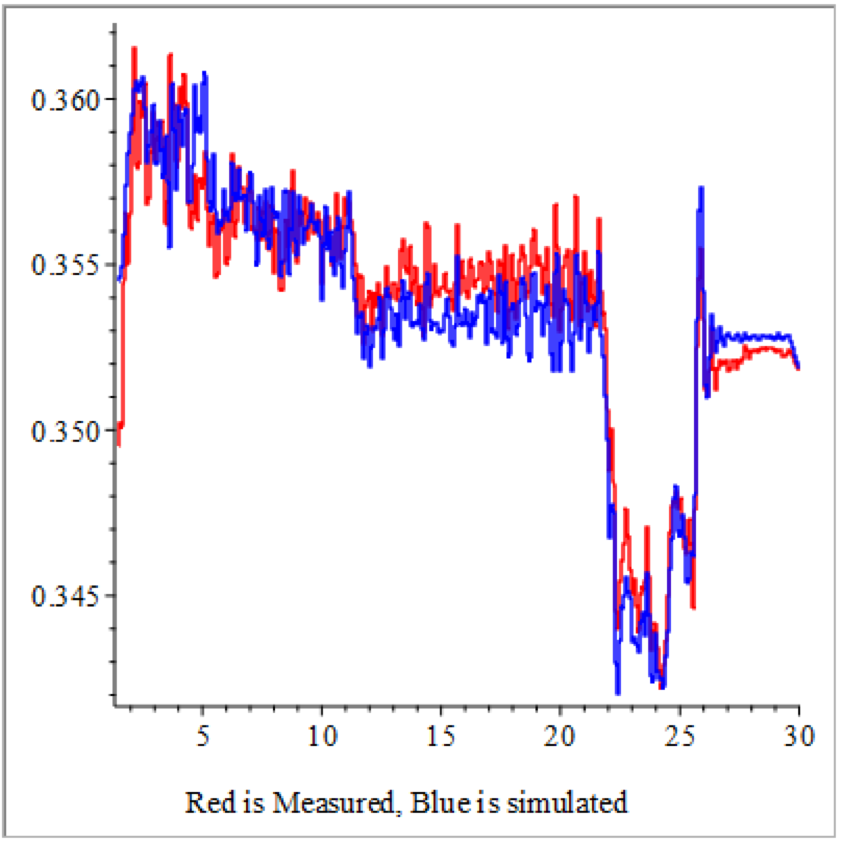

Initial test results are promising. The new tire model shows improved accuracy over existing models without resorting to more resource-intensive approaches. The researchers plan to use additional data from a Vehicle Measurement System to further fine tune the parameters of the model in MapleSim. The tire model can then be incorporated into detailed vehicle models for complete vehicle systems simulations.

Tires are a critical component in vehicle design. To save time and money in the design and development of new vehicles, automotive manufacturers typically use models to simulate the dynamic relationship between tires and road surfaces. Ideally, a tire model must accurately simulate the dynamics of the system and allow designers to vary its parameters, and simulations must also execute quickly.

Existing tire models have inherent drawbacks. Some existing tire models, such as the Pacejka magic formula tire model, are based solely on experimental data. Alternatives, such as finite element models, are extremely resource intensive, while other tire models represent the tire with a physical object, such as a string or brush. None of these models achieve an ideal balance of accuracy and efficiency. However, researchers at the University of Waterloo are taking a new approach to tire modeling with the ultimate goal of achieving this ideal balance.

The research team, led by Dr. John McPhee, Professor of Systems Design Engineering, and Dr. Joydeep Banerjee, Lead Researcher, used Maplesoft’s system-leveling modeling tool, MapleSim, to develop and test a volumetric tire model. “The volumetric tire model developed in MapleSim offers two distinct advantages over existing tire models,” said Dr. Banerjee. “Since the moments are calculated using kinematic data only, the model can be easily programmed for numerical simulations. In addition, the resistive torques are evaluated as functions of both normal load and angular speed of the wheel.”

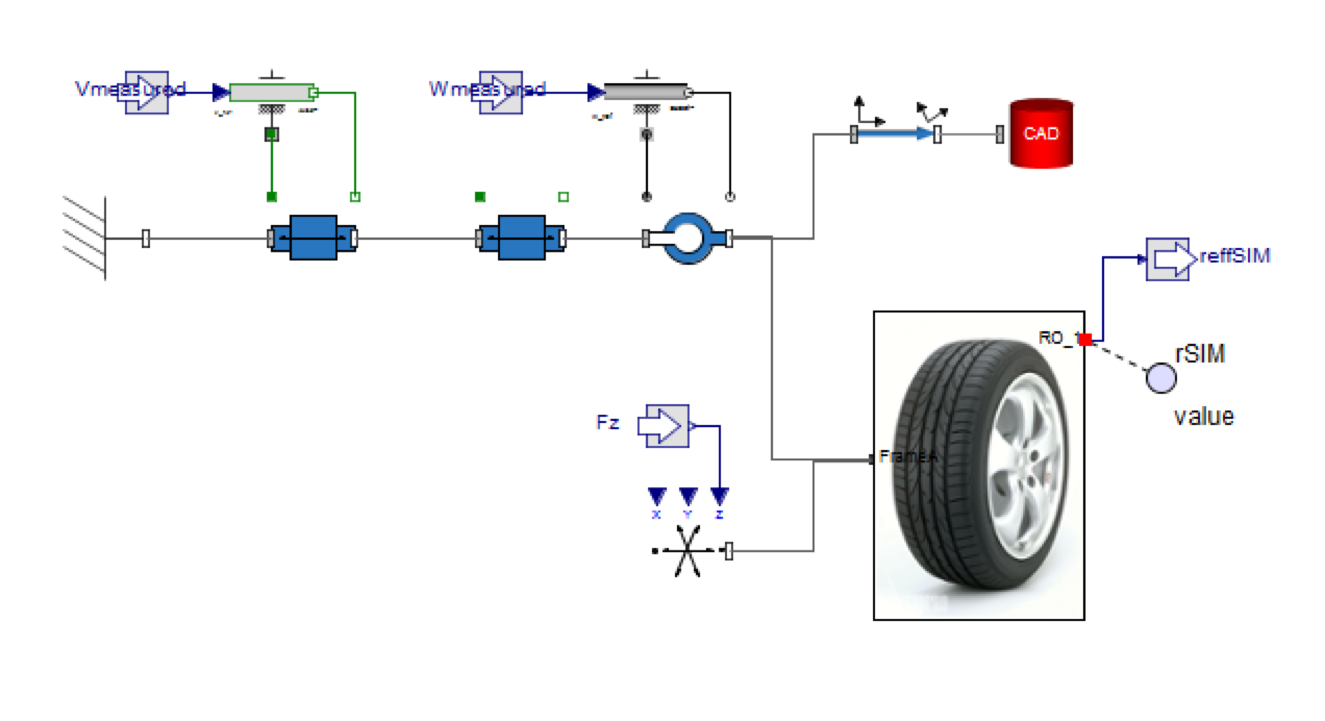

Using Maple, Maplesoft’s advanced computation engine, the symbolic expressions for the normal force and rolling resistance were derived as a function of the position and orientation of the tire. The distributed friction forces were symbolically integrated over the tire contact patch to calculate the traction forces and self-aligning moments. The researchers then used MapleSim to develop the model using custom components derived from the Maple expressions. The resulting volumetric tire model is shown in Figure 1.

Figure 1 - Volumetric Tire Model as developed in MapleSim

Figure 2 - Comparison of the Simulated and Measured Forces on the Volumetric Tire Model

Figure 3 - Vehicle Instrumented with VMS

Contact Maplesoft to learn how MapleSim can help with your projects

Contact Maplesoft to learn how MapleSim can help with your projects