Highlights:

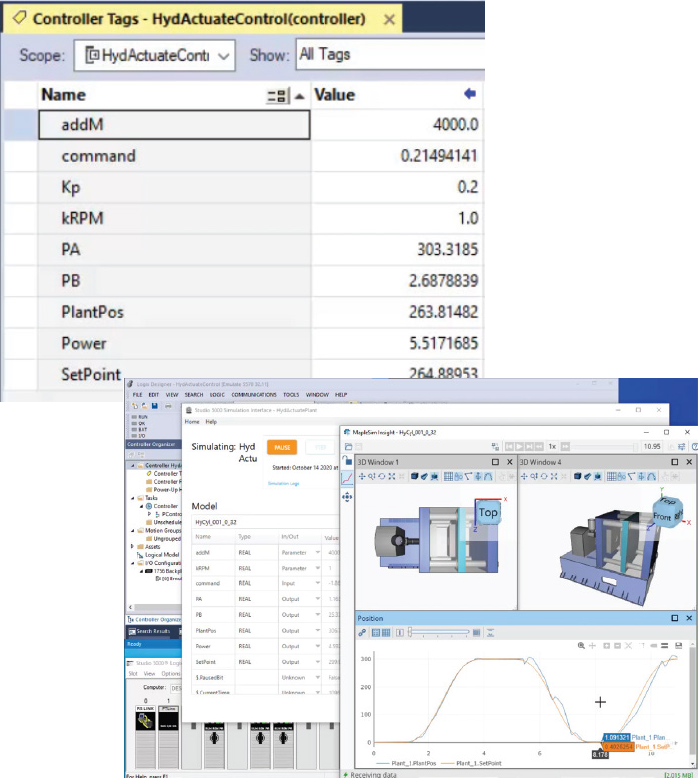

- Creating a virtual model of the system allows the control code to be tested before any physical prototype needs to be built.

- With a virtual commissioning process, design problems and PLC errors are discovered earlier, when it is cheaper to make corrections.

- Connecting your existing Studio 5000 software to a MapleSim model saves development time and helps build a better product.

Speed-to-market can make or break a deal. As a result, machine builders are constantly reviewing their development cycle in an effort to outpace their competitors. To deliver a high performing machine quickly, design engineers need to bring more factors under their control. This whitepaper outlines how MapleSim, from Maplesoft, can be used in combination with Rockwell Automation's Studio 5000 to speed up the development and commissioning of a new machine. More specifically, the virtual models built in MapleSim allow controller testing and physical build/design to happen in parallel — streamlining the development cycle and allowing earlier detection of design weaknesses. Once the machine is built, these models can be used to provide compelling enhancements to the functionality of the delivered machine.

Also available to read online