By Paul Goossens

The world of industrial automation is undergoing a major transformation to the Next Industrial Revolution, or Industry 4.0.

Manufacturers can no longer afford the "build it and tweak it" approach that has long characterized many design projects. Instead, they must take a more systems-design approach by implementing rigorous systems-design processes that accommodate the complexities of developing multi-disciplinary systems.

High-fidelity virtual prototypes, or Digital Twins, are at the core of this development process. There are countless ways a Digital Twin can be used in the world of industrial automation:

The world of industrial automation is undergoing a major transformation. Advanced computation and communications technologies have reached such a level of maturity that machine manufacturers are making dramatic changes in the way they design their products. A major shift from dedicated mechanisms to mechatronic, or cyber-physical, systems means that manufacturers and their customers are no longer constrained by the mechanical design of a machine. Instead, machines in which the mechanism's motions are defined by servo actuators and control software provide significant opportunities for flexible manufacturing, adaptive throughput, energy management and machine lifetime value. The resulting cost savings and competitive advantages are essential in industry today, as more and more manufacturers adopt these technologies into their next-generation products. Indeed, the evolution and convergence of many new technologies - mechatronic systems, controllers, on-board computation, Big Data, machine learning and the Industrial Internet of Things (IIoT) - are driving thought-leaders to talk about The Next Industrial Revolution, or Industry 4.0.

Products

Learn more about Virtual Commissioning and Digital Twins

Next Steps

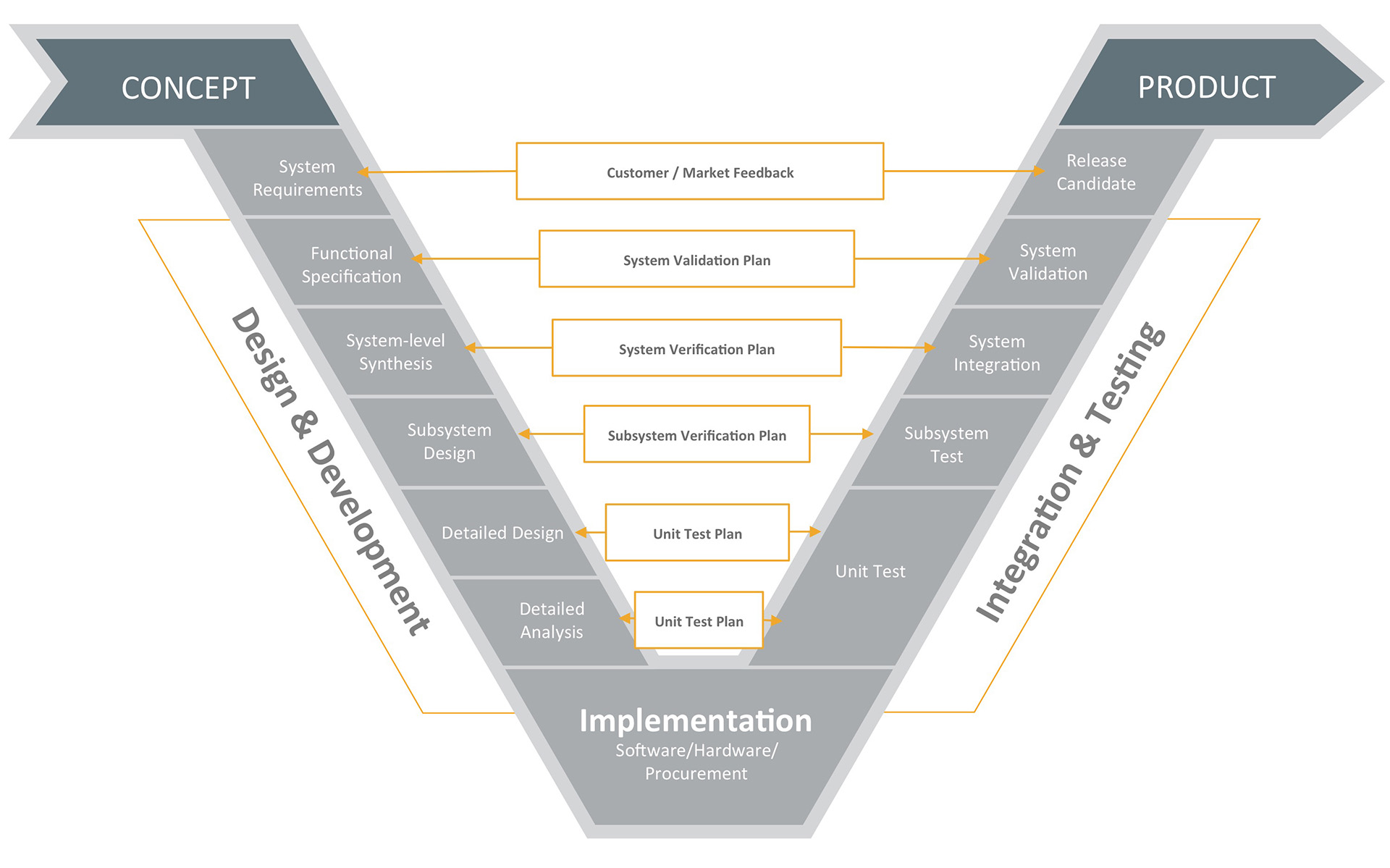

Manufacturers are being forced to challenge their own assumptions when it comes to their traditional design processes and practices. They can no longer afford the "build it and tweak it" approach that has characterized many design projects, and instead, must take a more systems-design approach that has proven to be an essential part of the design process within the aerospace and automotive industries for many years. Through formal requirements management, and the development of high-fidelity dynamic models used in simulations of the system, manufacturers can validate the design against the requirements in the early stages of the process. The resulting high-fidelity model from this process is typically referred to as the Digital Twin.

The Digital Twin is a concept borrowed from space programs. In this industry, often any changes to any of the systems on a vehicle, probe or rover during a mission, are tested on a simulation of the system to ensure any change produces the desired effect. This gives engineers the opportunity to address any undesired effects before applying the changes to the system in operation. Not long ago, the Digital Twin would have been developed from the ground up, based on the final specifications of the real system. However, with the advent of powerful easy-to-use mathematical systems-modeling tools, like MapleSim from Maplesoft, and rigorous systems-design processes, the Digital Twin often comes as a natural consequence of using simulation tools for functional verification throughout the design process.

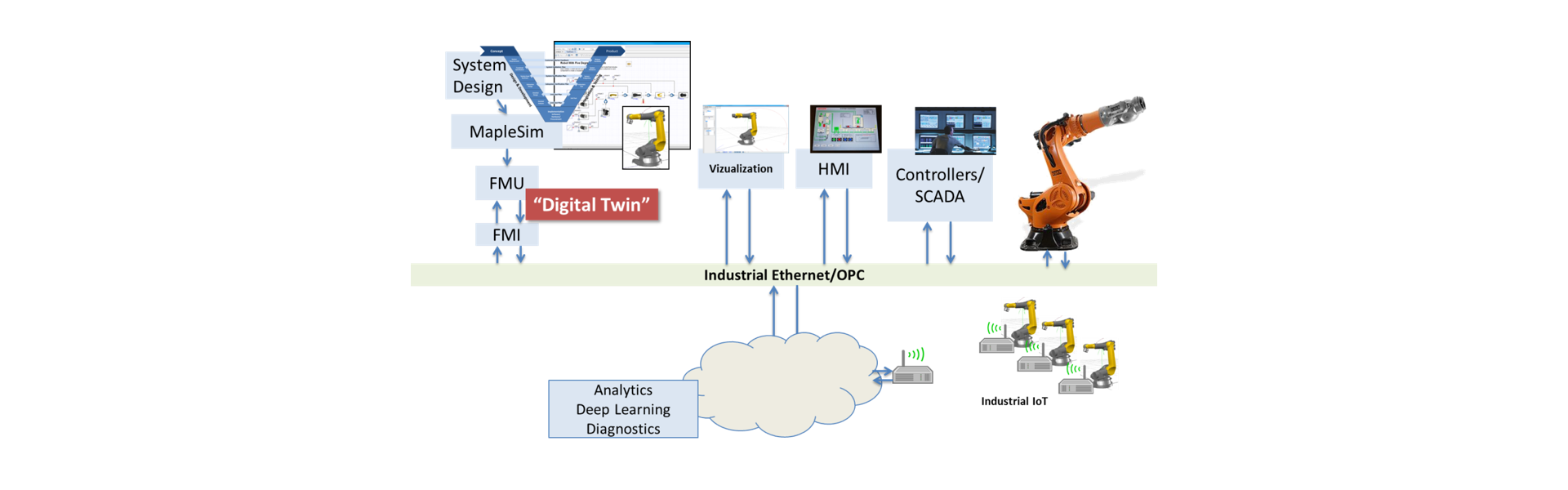

Most industrial automation platforms support the Functional Mock-up Interface (FMI) as a way of integrating a real-time implementation of the Digital Twin so it can be run in-line with the real machine. This allows for rapid task-planning and testing in the virtual world before any system changes are made to the real machine.

The cost to create dynamic models of multi-disciplinary systems has declined considerably over the past few years and is well within the budget of most manufacturing-machine design projects. It has been proven over many projects that identifying and addressing design issues early in the design process saves huge costs and associated disruption to the project schedule in late-stage design requests, particularly during prototyping or beyond. Therefore, the return on the up-front costs for tools and expertise to implement this process is very quickly realized.

In industry, the Digital Twin offers unlimited possibilities beyond the design process. For example, an in-line Digital Twin allows an operator to train on a virtual machine until they have the skills and confidence needed to operate the real machine, without the expense of a dedicated training simulator. Using an in-line Digital Twin accelerates the learning process and minimizes the risk of damage to the machine.

A Digital Twin can also be used to identify potential issues with its real machine counterpart. Imagine a scenario in which a high-fidelity physics model is running in parallel with the real machine and immediately identifies a malfunction (or potential malfunction) in the real machine. Any excessive wear in a component would be indicated by a drift between the machine's performance and the behavior of the model, which can be readily flagged. The model, that has exactly the same physical structure as the machine, could identify the source of variance within the model and provide indicators to the operator where the fault may lie, saving on machine life and diagnostic costs. Taking this a step further, if this same fault is not catastrophic, it would be possible to use the model to provide a strategy for compensating for a decrease in performance without slowing or stopping production. The emergence of optimal control and model-predictive control techniques, combined with advanced machine-learning capabilities, makes this scenario possible.

With the ability of systems to communicate remotely with the operator through IIoT technologies, it won't be long before we see increasing autonomy being implemented in the machines, much like we see in the automotive industry. The machines are not only communicating with the operator but also with each other or even with themselves! An embedded Digital Twin would provide the basis for increasing the self-awareness of the machine, allowing it to optimize its own performance for given duty cycles, diagnose and compensate for non-catastrophic faults, and coordinate operation with other machines with minimal input from the operator.

B&R Automation, a recognized leader in factory and automation software and systems, is using MapleSim on their Automation Studio platform. The use of MapleSim allows the machine designer to create a virtual prototype of the machine design, directly from the CAD representation, and integrate it as a Digital Twin on their real-time platform as a Functional Mockup Unit (FMU). In this way, the virtual machine can be configured and tested in parallel with the real machine to accelerate the commissioning process, reduce risks and decrease costs.

Whether or not you call it Industry 4.0, there can be no doubt that a major change in the way manufacturing systems are designed is unfolding. The convergence of mechatronic, or cyber-physical, technologies with advances in data management, machine-learning and communications is already challenging traditional industrial machine design processes. Manufacturers must begin to implement rigorous systems-design processes that accommodate the complexities of developing multi-disciplinary systems, with high-fidelity virtual prototypes, or Digital Twins, at the core of the development process. If they don't, these manufacturers will soon find themselves running behind the herd. The Industry 4.0 revolution is now. Early adopters are already benefitting from the power of the Digital Twin as part of their Industry 4.0 strategy. Through the acquisition and use of Maplesoft technologies that support this process, companies can easily implement Industry 4.0, realize its advantages and get ahead of their competition.

Forsberg, Kevin, Hal Mooz, and Howard Cotterman.

Visualizing Project Management. 2nd ed. N.p.: John Wiley & Sons, 2000. Print.

Warwick, Graham. "USAF Selects Lead Programs For 'Digital Twin' Initiative." aviationweek.com. Aviation Week & Space Technology, 26 Jan. 2015. Web. 19 Dec. 2016.

Cotteleer, Mark J., et al. "3D opportunity and the digital thread." dspace.mit.edu. Deloitte University Press, n.d. Web. 19 Dec. 2016.

Chan, Kelvin. "Robot Revolution Sweeps China’s Factory Floors." ecnmag.com. ECN Magazine, 24 Sep. 2015. Web. 19 Dec. 2016.

MA Staff. "Factory of the future will reduce conversion costs by up to 40%: BCG." automationmag.com. Manufacturing Automation, 13 Dec. 2016. Web. 19 Dec. 2016.

Küpper, Daniel, et al. "The Factory of the Future." bcgperspectives.com. Boston Consulting Group, 6 Dec. 2016. Web. 19 Dec. 2016.

Grant, Tavia. "Rise of the machines: Robots poised to transform global manufacturing." theglobeandmail.com. The Globe and Mail, 10 Feb. 2015. Web. 19 Dec. 2016.

Bagheri, Behrad, and Jay Lee. "Big future for cyber-physical manufacturing systems." designworldonline.com. Design World, 23 Sep. 2015. Web. 19 Dec. 2016.

"Virtual testing for greater simulated and actual success." boschrexroth.com. Rexroth Bosch Group, n.d. Online video clip. 19 Dec. 2016.

Monostori, László. "Cyber-physical production systems: Roots, expectations and R&D challenges." Science Direct Procedia CIRP 17 (2014): 9 - 13. Science Direct Online. Web. 19 Dec. 2016.

"Packaging Machinery Designers Face Five Big Challenges, says DS SolidWorks." businesswire.com. Business Wire, 18 May 2009. Web. 19 Dec. 2016.