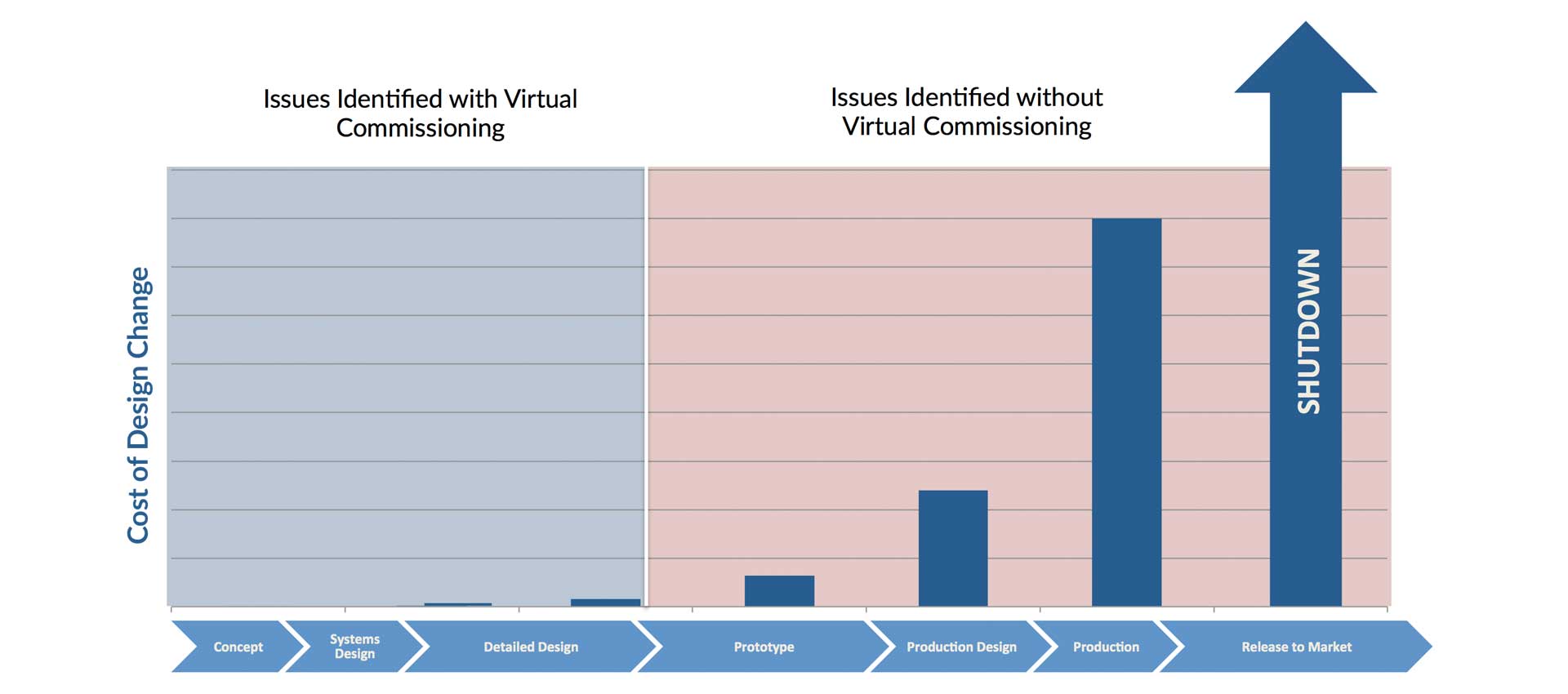

Virtual commissioning sounds great in theory. Take a virtual prototype of your machine and hook it up to a virtual PLC, and test your product virtually before you test it physically. Early testing lets you identify problems sooner, so you can make any necessary design changes before the expensive physical integration phase. As a result, you save time, money, and headaches. What's not to like? And you know that other industries, like automotive and aerospace, have been using virtual modeling and simulation as part of their development process for years, very successfully.

But your current development process does work, and changing any process is a hassle and comes with its own costs. How can you tell if adopting virtual commissioning would be worth it? And even if it is, is virtual commissioning truly a feasible option for your company today?

Products

Learn more about Virtual Commissioning and Digital Twins

"If it ain't broke, don't fix it" is often good advice. But sometimes a situation is so familiar that it is hard to recognize it as broken - it just feels normal. So here are some questions to ask yourself:

And consider this. If you were using virtual commissioning to develop, refine, and test your products, you most likely would have:

Okay, so the benefits are substantial, and if you could wave your magic wand and have virtual commissioning implemented in your company tomorrow, you probably would. But it's never that simple.

You may have looked into virtual commissioning a few years ago, and decided that it was too difficult to implement. Even as recently as 2010, practical implementation of virtual commissioning was deemed out of reach, as it was too difficult to create the models, and too difficult for such models to work in tandem with PLC development software (Hoffmann et al. 2010).

But since then, modeling technology has advanced greatly. It is now possible to create Digital Twins using physics-based modeling techniques rather than data. A model-driven Digital Twin can help you realize the benefits of a data-driven Digital Twin, without having to manage the challenges of expensive sensors, data collection, and black-box behavioral algorithms. Additionally, because it doesn't need test data to predict behavior, the model-driven Twin can be used for conceptual design work, before any physical prototype has been constructed. Once a design has been chosen, it can be connected to your controllers to test integration in a virtual commissioning phase, ironing out the issues you'd otherwise find on the production floor.

As a result, today's model-based digital twins put the benefits of virtual commissioning within reach even for smaller automation companies.

But how can you get started? You have talented engineers at your company, but chances are they are not experts in physics-based modeling and the creation of Digital Twins.

Drawing on decades of experience, Maplesoft Engineering Solutions help automation companies implement virtual commissioning using model-based Digital Twins. Maplesoft can work with you to develop your models and integrate them into your development process, or if you prefer, provide the tools and training so you can do the work yourselves. Maplesoft can provide assistance in a variety of ways, such as:

Willem Fourie, Development Manager, FLSmidth

See Digital Twins for Virtual Commissioning on the Maplesoft web site for more information about Digital Twins and how they work, examples and case studies, and information about the products and services Maplesoft offers.

Virtual commissioning provides undeniable benefits to automation companies, from reducing cost over-runs to lowering risks, shortening development cycles, and making you more competitive. With the advent of model-based Digital Twins, virtual commissioning is now significantly more affordable and more manageable, making it a viable option for even small companies. Maplesoft has the expertise, technology, and experience to help make virtual commissioning a reality for your organization.

The digital model is a virtual representation of a corresponding physical product. It can be used to simulate, predict and analyze machine performance. These models can range widely in their purpose and fidelity, but they serve as a powerful connection to the product for diagnostics, design changes, and virtual commissioning. Companies are using digital twins across industries, allowing them to optimize their products in ways that were previously impossible.

Hoffmann, Peter & Schumann, Reimar & Maksoud, Talal & Premier, Giuliano. (2010). Virtual Commissioning Of Manufacturing Systems - A Review And New Approaches For Simplification. Proceedings - 24th European Conference on Modelling and Simulation, ECMS 2010. 175-181. 10.7148/2010-0175-0181.