In the marketplace of technical products, growing competition has required faster design cycles and iterations in almost every sector. Companies take great steps to invest in their most important assets - namely, the products they deliver. These products are comprised of various designs, techniques, and intellectual property, all of which are managed across an organization with careful thought and attention.

There's a fundamental process behind these company assets that is often overlooked, and its lack is responsible for aches and pains that most engineers face on a regular basis. What's often missing is calculation management, a process that treats your calculations like the vital, valuable company asset they are.

Consider the workflow of many engineers or technical professionals. During beginning stages, there's a lot of scratchpad work to be done as the concept moves closer to reality. Without enough care and attention, these calculations find themselves spread out over notepads, spreadsheets, and simply in the engineer's head. As the design moves forward, these calculations become bundled into all future decisions - for better or worse. What happens if an engineer moves on, or is on vacation? Without the original author, engineers can be left scratching their head and wondering where "that" number came from.

Calculation management is a strategy that systematizes the way an organization manages its mathematics and knowledge, from start to finish. With best practices and proper software, calculation management promises to:

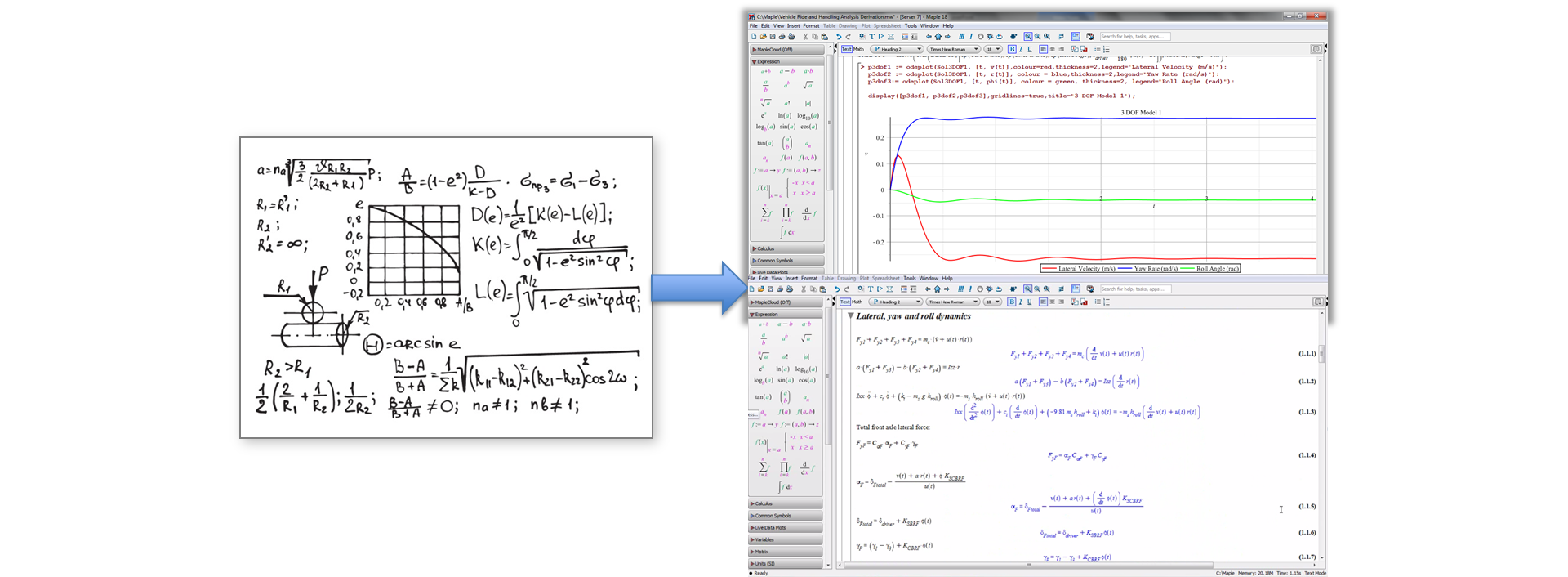

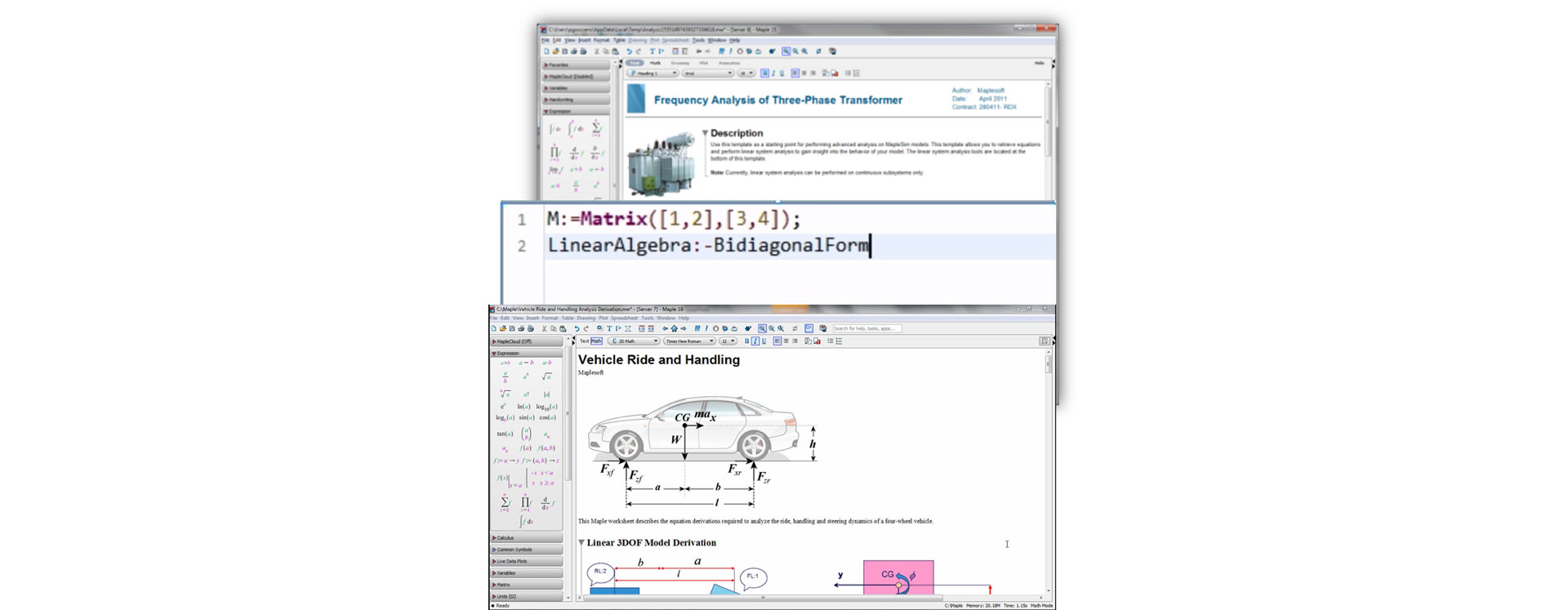

It's important to understand that the nature of engineering calculations often requires more than a spreadsheet tool. While these tools are useful for simple computations, they don't provide the abilities to make calculations a robust, long-standing asset in a company. Engineering calculations are both a function of complex mathematics and physics-based computations, complete with specialized functions and a wide spectrum of units. For these calculations to be reliable in large designs, they'll typically undergo a validation process, so they must be in a tool that allows the full range of derivations to be transparent, well-documented, and easily updated. The calculations themselves are often a description of real, complicated physics, so they are best performed using tools that are optimized for efficient calculations - even better if these tools can support the power of cloud computing.

Here at Maplesoft, we've heard first-hand how companies benefit when they take a more structured approach to calculation management. What follows are the stories of two companies that used Maple to take a more robust approach to calculation management.

In the current climate of industrial trucking products, truck manufacturing companies are striving to improve their products in more efficient ways than ever. These improvements can come in many forms, but in an industry of expensive prototypes and stiff competition, it is critical to find innovations that fit within tight margins, fast development cycles, and that deliver guaranteed reliability in the field. Regardless of the particular innovation, it will require some amount of careful calculations to ensure that the concept is feasible.

The engineering department at Hitachi Construction Truck Manufacturing (HTM) is taking steps to improve their rigid-frame hauling truck design through improving their analysis tools. The company has a history of using spreadsheet programs and older coding languages as a means to solve some engineering problems. While sometimes sufficient, these legacy approaches to managing intellectual company property can end up introducing redundancies and slowdowns in a variety of ways during a design process. The engineering department at HTM decided to gradually implement the use of Maple in several key areas to help speed development, and reduce the risk of errors from manually handling calculations across many tools.

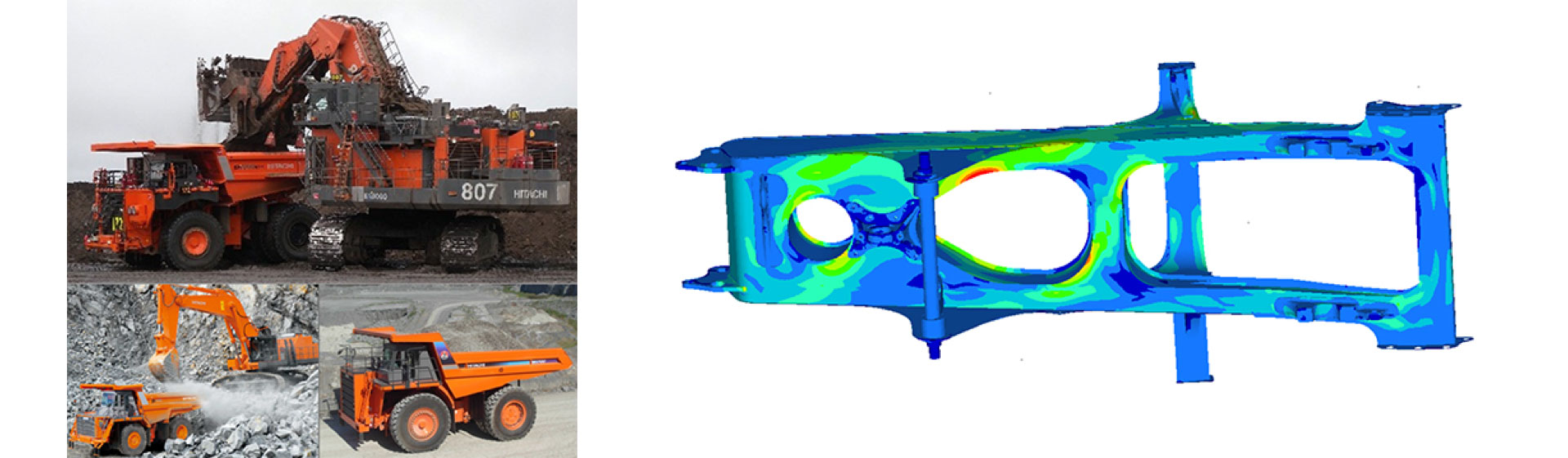

Left: Figure 1:

The rigid frame trucks developed by HTM must endure heavy workloads, and to avoid unexpected failures, their analysis team must ensure their calculations are error-free

Right: Figure 2:

Performing FEA work is often very time - and resource-intensive. By using Maple, Dr. Shen is able to quickly approximate material stresses and use FEA to perform only the final leg of analysis.

During typical analysis tasks at HTM, engineers use specific mathematics to work through design concepts, model their kinematic behavior, and analyze their structural integrity over time. In the truck's initial design stage, HTM has historically used some developed spreadsheet programs, but has recently moved to Maple to reduce the chance of errors and improve calculation efficiency. In addition, Maple has been adopted to optimize design parameters throughout the truck design process. "Using Maple can make calculations more efficient than using spreadsheets," noted Dr. Shen, a senior manager of the technical analysis group, when explaining his past experience using spreadsheet tools for analysis work. Using Maple, HTM engineers can set up their analysis with an intuitive math input, and use built-in functions to automatically solve and simplify work, reducing many of the possible errors they had associated with traditional, manual effort. The rigid frames developed at HTM must support massive payloads ranging up to almost 300 tonnes. To make sure these frames are suitable for the job, HTM uses finite element analysis (FEA) to investigate the life of welded joints, helping to determine the required size of each weld. While FEA is a powerful tool, it can be very resource-intensive, slowing down critical aspects of design analysis. Using Maple, HTM engineers perform initial stress estimations that give them a much better sense of their design before spending large amounts of time doing FEA iterations. With a better starting point, the FEA work is already honed in on rough approximations, so it can arrive at accurate solutions much quicker.

In addition to improving the analysis capabilities of HTM, engineers are also beginning to integrate Maple into the reports they must regularly create for records. In the past, these reports would be an entirely different task, and any necessary mathematics would be inserted as screenshots, creating a break between the actual analysis and the report itself. With Maple, the documentation interface offers all of the features necessary for professional reports, and the mathematics involved are live, allowing updates to be reflected immediately across the entire document. Although still in the beginning phases, HTM engineers can now use Maple as a means to easily create reports from their pre-existing analysis work. As time goes on, this will allow engineers to create a live connection between their analysis work and their reporting, ensuring that future changes are reflected across all the relevant documents at hand.

By adopting Maple as a tool for calculation management, HTM is joining the growing number of organizations that are treating their engineering calculations as an essential company asset. Responding to an increasingly competitive market, HTM is finding success by reducing the many sources of inefficiencies caused by legacy calculation tools. The success that HTM is finding with Maple is the result of treating calculations as a structured asset, ensuring they are created, reused, and distributed with care and attention. The migration from old techniques still continues, but HTM engineers are already seeing the benefits of adopting Maple for a variety of tasks that were once performed in older, general-purpose tools. With proper calculation management tools in place, HTM is creating powerful, efficient tools that reduce development risk and get their products to market faster..

As the Superintendent of Process Technology at Diavik, Yuri Kinakin uses a host of analysis techniques to ensure that Diavik is using the best techniques available for processing their materials. Traditionally, they relied on spreadsheets and other mathematical software to coordinate their workflows and analyze them for accuracy and improvements. Recently, Yuri moved some of Diavik's analysis requirements into Maple, the calculation management tool from Maplesoft, in order to simplify their calculations and provide better insight compared to what was available with their previous tools.

The large amount of parameters involved in Diavik's processes can result in some complicated calculations. The matrix multiplications they perform have traditionally taken more time and effort to complete than necessary. "We use our spreadsheet tool more than we want to," Yuri noted. "Maple just made it easier - calculations we used to do in previous tools can be done in Maple using only a few lines."

Another common task for Yuri and his team requires fitting curves to a set of throughput data they gather regularly. They are interested in finding the probabilities that their throughputs will exceed specific quantities; thus accurate probabilities become valuable information in each process plan. Instead of doing polynomial fitting in other tools, Diavik used Maple's curve fitting package, which was designed specifically for this kind of work. Using Maple, Diavik was not only able to get accurate fits for their process data, but they could provide transparency for their analysis, making calculations easy to understand across the entire team.

As Diavik takes positive steps to manage their process calculations better, they hope to use Maple for even more of their work. Similar to many technical organizations, they are still reliant on a variety of spreadsheets that, while functional, don't provide them with the flexibility or simplicity they need. "Our spreadsheets can be unnecessarily complicated, and over the years, we've seen them grow into something very big and clunky," Yuri commented. As more calculations are transitioned to being managed by Maple, Diavik hopes to provide easier, more auditable reports that allow other teams to validate the work being done.

Although Yuri has only been using Maple at Diavik for less than a year, he has already experienced time savings in his process planning. By making complex calculations easier to perform, Yuri has been building a stronger foundation of calculations that can provide more accurate solutions to the questions he had previously been trying to answer using spreadsheets.

Yuri's approach to calculation management is a sign of the growing need across industries to treat calculations as a valuable, structured asset. Of course, many professionals have their own personal preferences for where to do their calculation work, and adopting new tools can be hard to justify. Spreadsheet-based tools have become ubiquitous for quick and simple mathematical needs, but many companies only explore new tools as a reaction to the problems they've run into. By that time, they're already experiencing losses from their underperforming tool, and pressures to find a replacement run high. The current pace of technical projects requires a proactive approach to managing calculations properly, in a way that cuts out the redundancies and downtimes associated with the often-disorganized techniques of the past. By using Maple to perform calculations in a robust, fully-documented environment, Yuri is helping Diavik make the most out of the intellectual property they've been building over their decades-long history.

Adopting a calculation management tool is an essential step when making calculations a structured, validated set of assets across a company. Maple also functions as a documentation system, ensuring that calculations are understood and accessible across an organization. Using natural math notation, engineers can perform their calculations just as intuitively as by hand, while using plots, diagrams, and text to create mathematical documents that are report-ready. Employing a tool that automatically takes care of common tasks frees up an engineer's time to develop specific solutions, explore new design ideas, and collaborate with others.

Many engineers have their own personal preferences for where to do their calculation work, and adopting new tools can be hard to justify. Spreadsheet-based tools have become ubiquitous for quick and simple mathematical needs, but many companies only explore new tools as a reaction to the problems they've run into. By that time, they're already experiencing losses from their underperforming tool, and pressures to find a replacement run high. The current pace of modern engineering requires a proactive approach to managing calculations properly, in a way that cuts out the redundancies and downtimes associated with the often-disorganized techniques of the past. It's time to treat your calculations as an essential company asset, and manage them with the attention they deserve.